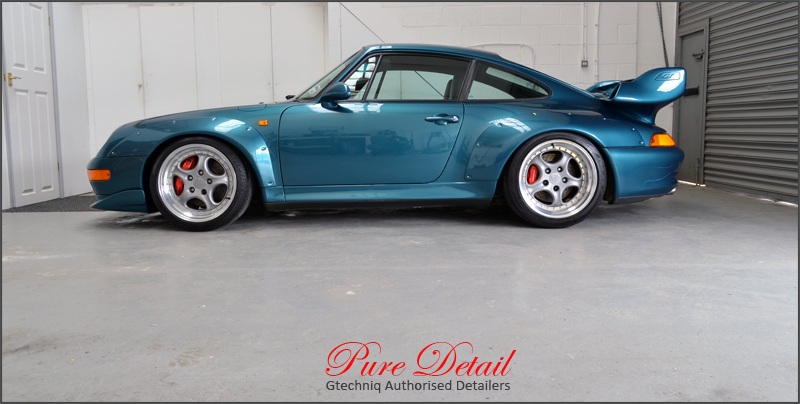

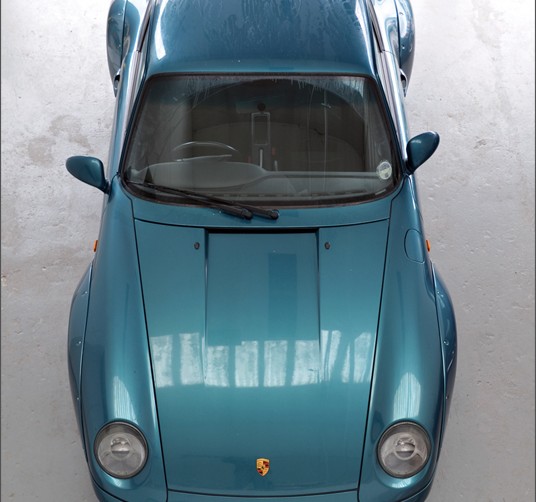

Porsche 993 GT2 RHD – One of eight ever made.

We were lucky enough to be given the chance to fully detail the exterior and interior of this rare Porsche.

Being only one of eight ever made in right hand drive, this low mile example was in need of paint correction and deep cleanse to the interior.

As it arrived with us:

The paint had worn the years well and obviously been looked after well, but was in need of deep paint correction in places and general restoration of the paints condition. After a discussion with the owner, it was agreed that the stone chips in the paint should be left as to the patina of the vehicles history.

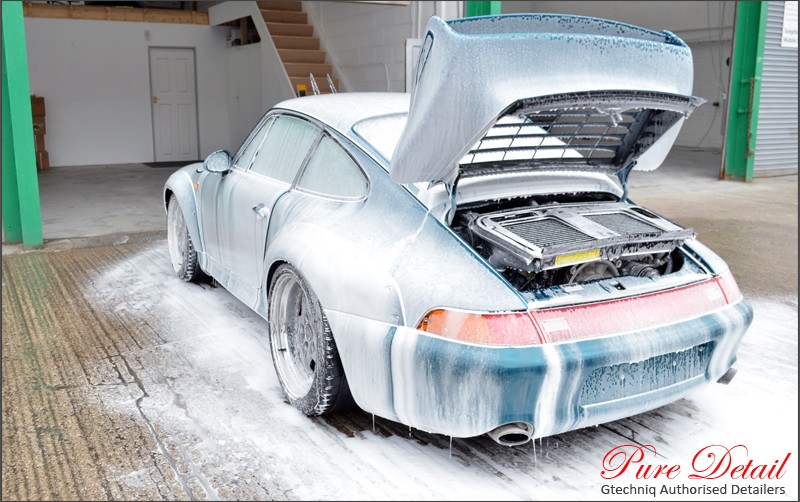

Onto the deep cleanse wash stages:

Pre-wash foam down to remove lose contaminates:

Engine bay detail – degreasing soak/wash

After the pre-soak and initial wash down, all the hard to reach areas and body lines were cleansed with the use of various brushes, tools, shampoo and degreasers:

Engine bay areas worked over as per the rest of the car and them steam cleaned in areas:

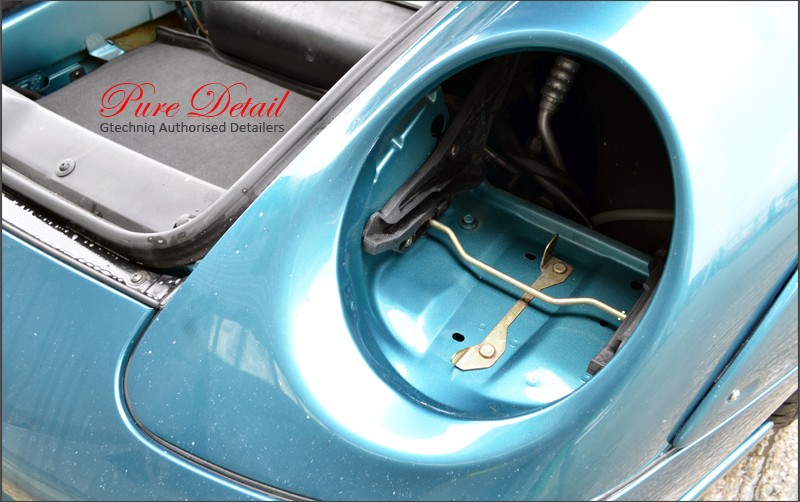

Headlights removed for access:

After the deep cleanse stages were completed, bonded contaminates still remained which require de-tarring, de-ionising and claying stages:

As you can see, still a lot of contaminates remained after wash/cleanse stages:

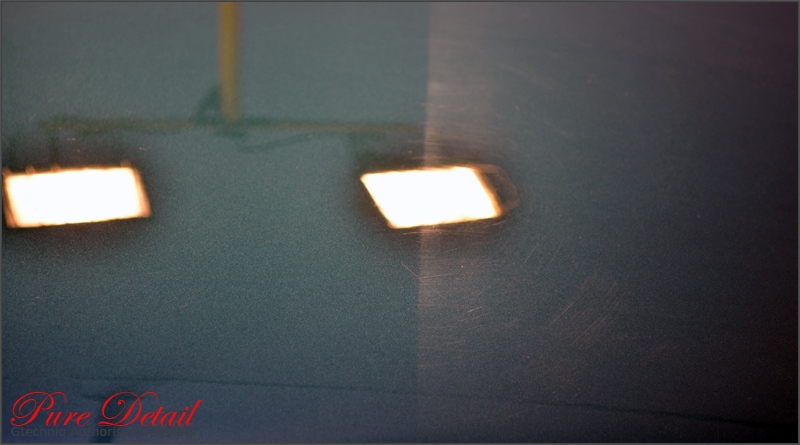

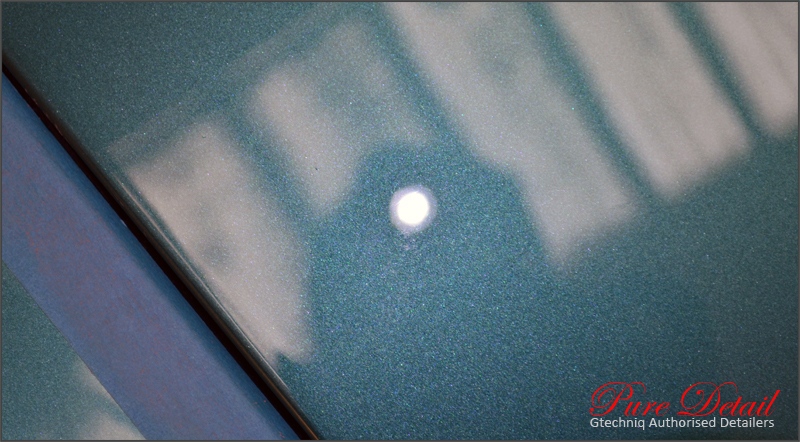

Once complete, the car was dried using flood technique, air drier tool and drying towels. Once inside it was time to inspect the paint further:

Ready for inspection and paint testing:

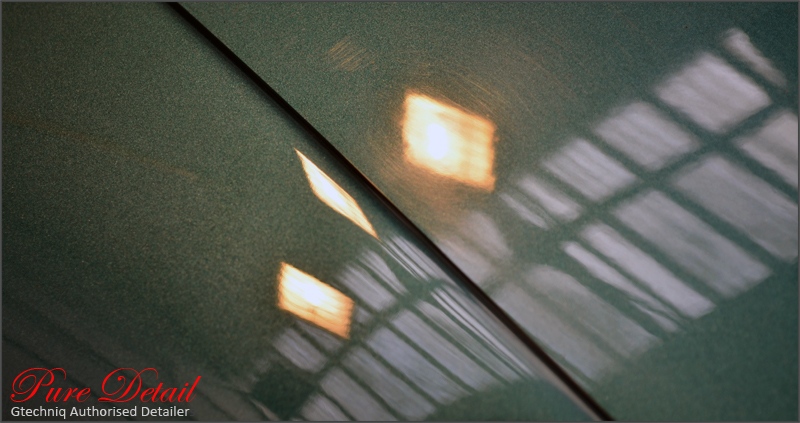

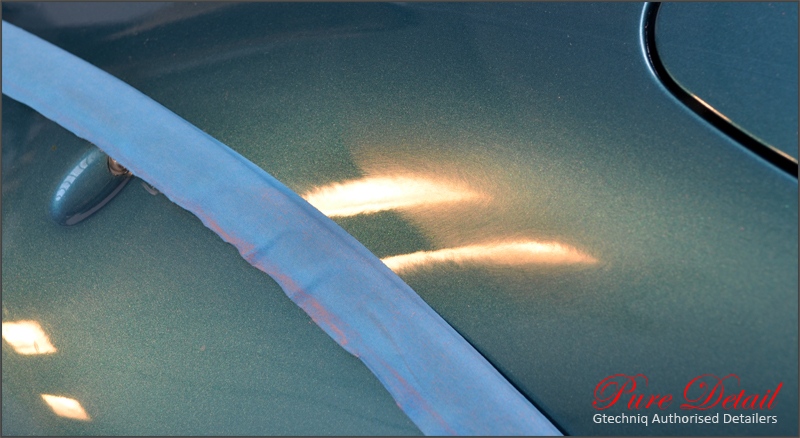

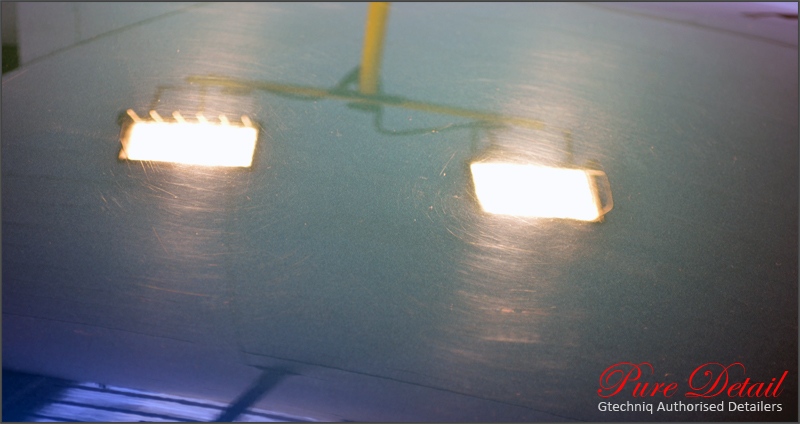

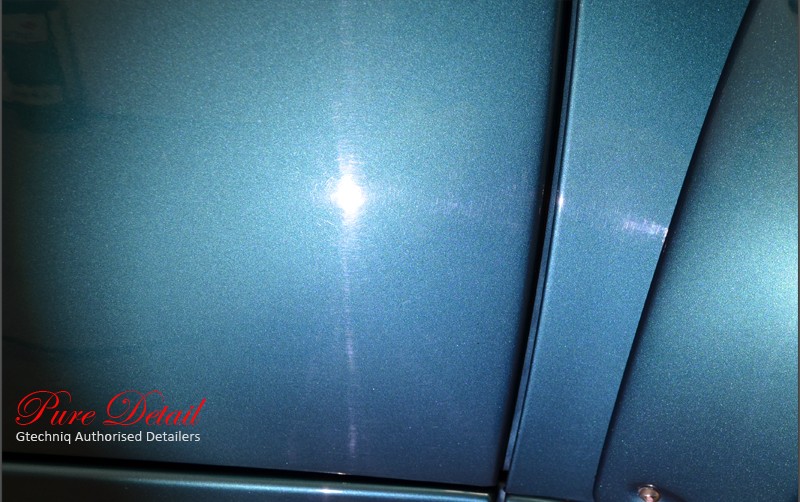

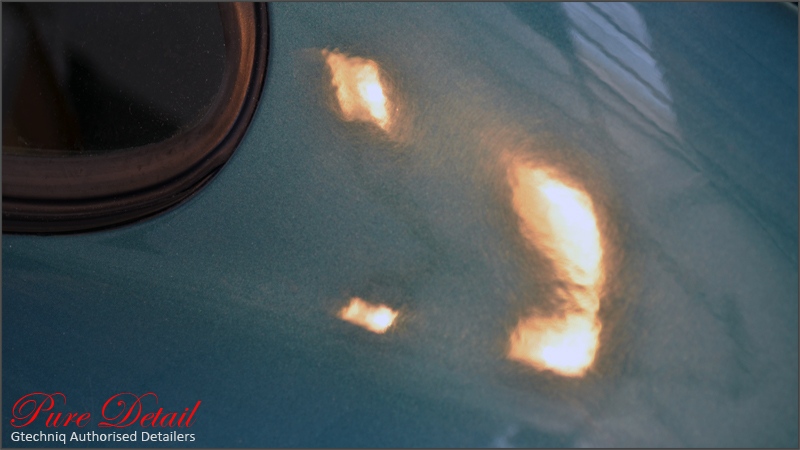

Very dull rough areas that have very little shine or reflections:

Some areas appear to have had some sanding marks which were not properly polished out:

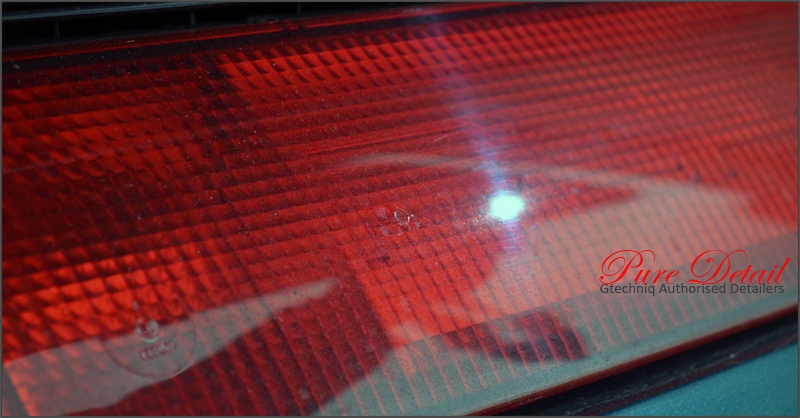

Plastic rear lights heavily swirled:

Having tested various pad and polish combinations, the Meguiars MicroFibre system performed the best for correction stages and 3M finishing pad and 3m ultrafina for finishing gloss stages.

After the twin paint correction stages:

And some before and after shots:

Onto the rear wing area. After the top of the rear wing was corrected, access was a problem so we carefully removed the rear wing noting the position holes.

Upper wing part way through correction – 50/50

Hainvg access – we were then able to polish thehard to reach areas with ease:

This useful extension bar meant it was possible to access the air scoops:

Also allowing access to polish the wheel lacquered dishes:

Once the hours of paint correction were complete on the main part of each panel, we then ensured all the edges were fully corrected…

Finishing machine polishing stages were then carried out to ensure a flawless deep glossy shine, ready for panel-wipe and IPA wipe down. Then it was time for coatings to be applied:

Polish residue removed from panel edges:

Thank you very much for reading.

PD.