Key Details:

1. Deep cleanse and removal of fine bonded contaminates.

2. Twin stage corrective machine polish to remove oxidisation and hazing to leave high shine and smooth surface.

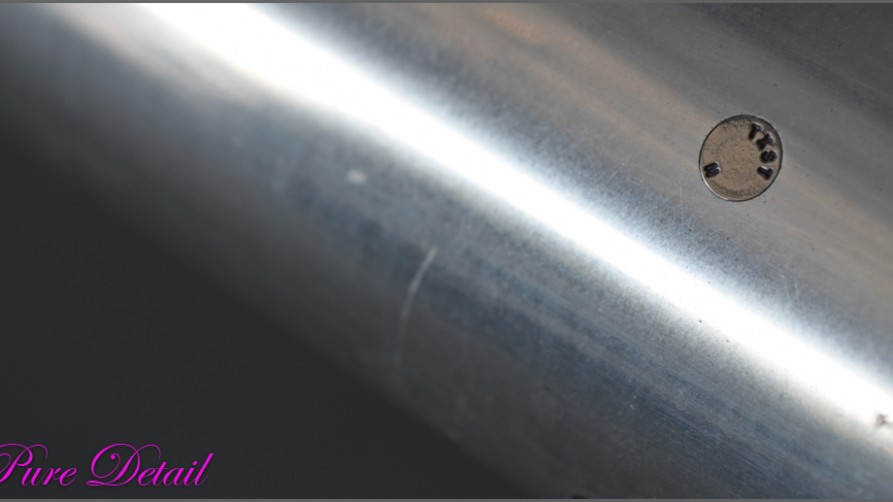

3. Restoration of leading edge bright work metal from heavily dulled rough finish to high shine and smooth finish.

4. Very durable protection to protect against extreme conditions and temperatures in the form of G-Techniq Exo.

Having detailed a private jet already for the maintenance company entrusted with looking after these multi-million pound jets, they contacted us to restore this larger private jet in need of more attention.

Once we passed all the security points, we moved straight onto the inspection. On first sight we were immediately taken in by the pure size of the jet plan and it was clear, 5-6 days would be needed to complete the detail.

The leading edge bright work would need the most attention, due to the damage caused over time and the importance of the leading edges.

Before:

After initial machine cutting stage,

50/50 shot illustrating the difference before and after metal cutting stage,

Moving on to the paint – being a polyurethane paint, it had oxidised despite regular ‘polishing’ by a local valeting company and needed a twin stage machine polish. Testing various pad and polish combinations, a medium pad with a heavier polish was most effective at ridding the oxidation and marring – whilst the second finishing stage left a sharp high shine reflection.

Here is a 50/50 showing before and after and the oxidisation damage…

After the twin stage correction the paint was very smooth and had a sharp high shine reflection to it..

Landing gear deep cleansed and protected on non mechanical areas…

Finished Business Jet…

Metal work after twin stage polishes,

Paintwork complete…

Thanks for reading.

Pure Detail.