Gtechniq Silver detail + extra machine polishing stages.

Booked in whilst the customer was away on holiday for two weeks, the R8 was in for deep cleanse, full exterior correction and G-Techniq protection + 5 year warranty.

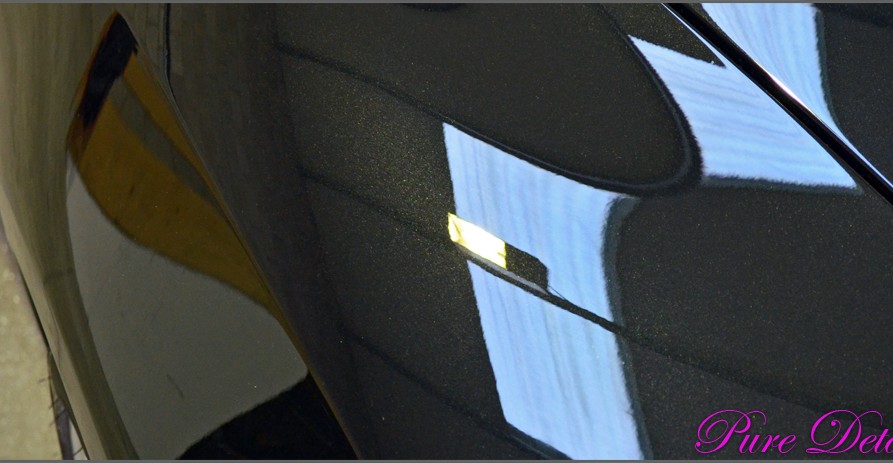

Upon inspection the paint had very deep defects towards the rear of the car where the panels are made of a composite material. On closer inspection, it appears someone has previously worked on this area causing a lot more damage and very deep marks. The main panels affected were the rear quarters and panels to the left and right of the engine cover. Being of a composite material, when machining, the panels can heat up a lot faster which to the untrained, can cause problems. The rest of the car had medium swirls and some scratches but nothing out of the ordinary.

As the R8 arrived,

Onto the wash and deep cleanse stages,

Wheels worked over with woolies,

After.

Final soak and wash down using G-Techniq G-Wash shampoo,

Once inside it was dried and prepared for the correction stages.

There was an odd contamination slick on the windows all round that the deep cleanse stages didn’t remove,

Nothing that a strong IPA mix couldn’t remove.

On to the rear of the car and the deep scratches/defects,

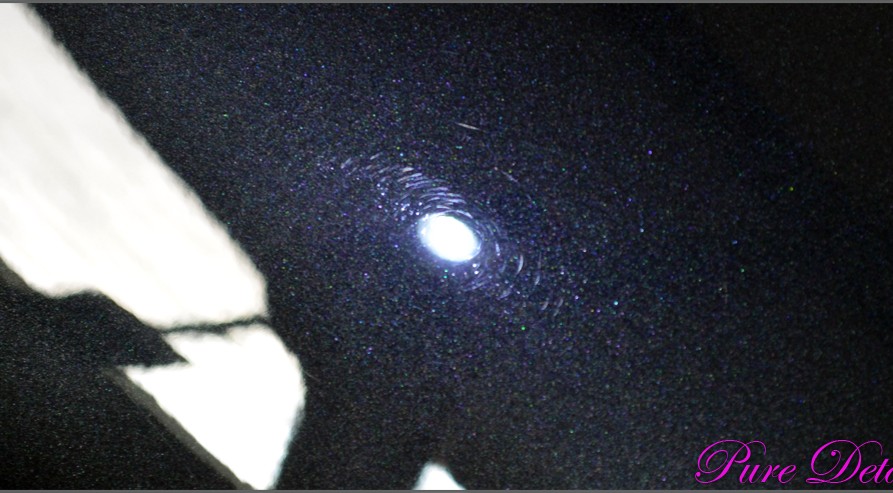

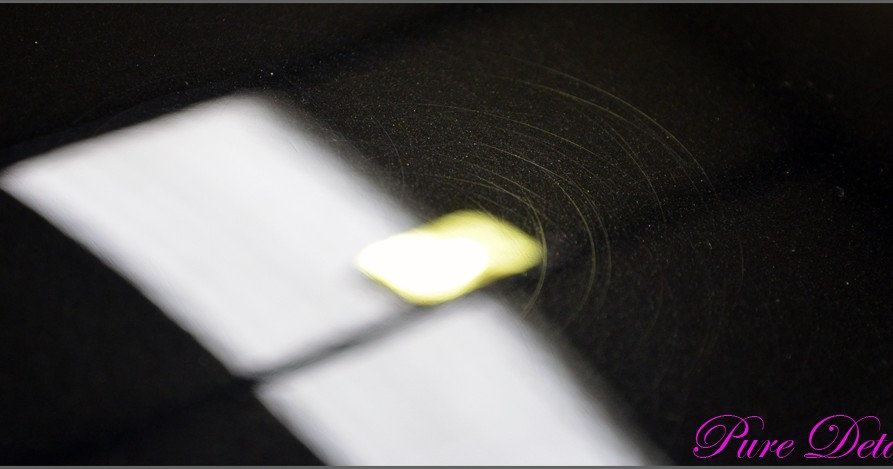

Circular machining marks possibly caused with a dirty mopping head or heated lacquer built up gradually into a small hard spot in the mopping head.

Onto the drivers side and note the two straight scratches, this could have been the reason for the previous machining. Also you can see the composite weaver has been raised which can also be caused by too much heat + thinned lacquer.

Tighter scratching and random orbital marks also visible.

Having tested the deeply scratched areas it was clear they were beyond machining. But we weren’t about to let them beat us. Talking to the customer, we opted to re-lacquer the damaged areas leaving a perfect defect free finish. Unlike re-finshing the area the paint is original – simply masked off and a layer of clear lacquer added. As you can see, flawless.

Once this problem was rectified, it was time to paint correct the rest of the car to the same swirl and scratch free finish. Multiple machine stages were carried out to achieve the desired finish.

Rear lights before and after correction stages,

After

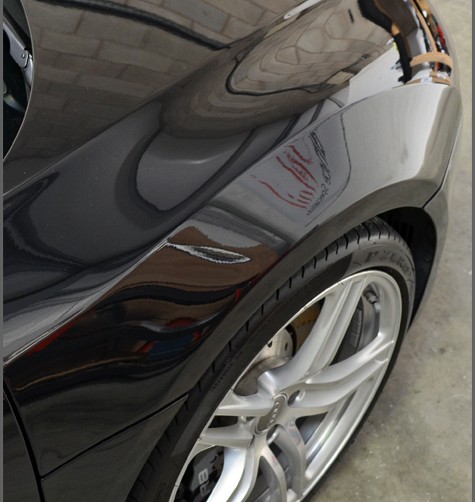

Paint finish after 60+ hours of machining – simply paint at this point, no gtechniq added yet.

After first stage…

After final finishing stage…

The roof was then applied with multiple layers (over the course of a few hours) of G|Techniq I1 Fabric protectant, which leaves the fabric as new, with a very dark finish…

Wheels coated and protected with G|Techniq C5 and tyres with T1…

Windows triple treated with G|Techniq G1

The paint was treated to G|Techniq C1 composite ceramic lacquer…

The finished results..

and finally outside with the customer…

Thanks to all involved,

Pure Detail.